User benefits include the ability to continue using models from previous versions of EEC. The new version of the configuration solution naturally builds on proven technology. Innovative development competence, a consistently practical approach, and international presence are the resulting success factors.Eplan Engineering Center is becoming Eplan Engineering Configuration The solution provider develops customer-specific and tailor-made PDM and PLM concepts and provides comprehensive services such as customizing, consulting and training. Interdisciplinary expert systems assure the highest degree of productivity and data integration.

#EPLAN EEC ONE SOFTWARE#

Assembly design however is always done in Eplan.”ĮPLAN Software & Service develops engineering solutions, which accelerate the product development process. But when we decide for ourselves which program we use, we choose Eplan. GreyLogix follows the wishes of its customers in selecting the engineering tool: “We use nine different ECAD programs.

#EPLAN EEC ONE PRO#

The engineers turn over the designs and are also responsible for initiating orders and printing out the wiring diagrams.” Both the customers and the sales department appreciate the 3D layouts generated in Eplan Pro Panel. “These three colleagues originally worked in production,” Besser says. Automation is well advanced here, too: sheet metal processing is performed directly from the CAE system – Eplan Pro Panel – on a Perforex machining centre from Kiesling.Īssembly design of control cabinets using Eplan Pro Panel are carried out by experts who are solely responsible for this task. A large planning board at the front of the hall displays the current cycles in which the individual products are structured and work stations are staffed. As the components run through the production process, each control cabinet panel is placed on a specially built assembly cart, which enhances flexibility. The available components are assembled according to the Kanban system. “For instance, engineers can just as well set up all the device tags in Eplan Electric P8 – it’s their choice.” The advantages GreyLogix sees in automated electrical engineering are so big that the company is currently considering introducing a similar concept for software programming: as Besser notes, “We would be able to shave off an additional 10 to 15 per cent of the hours necessary for this very time-consuming task.”įor control cabinet manufacturing, GreyLogix does this without a warehouse. “You don’t have to handle everything in EEC One,” Besser says.

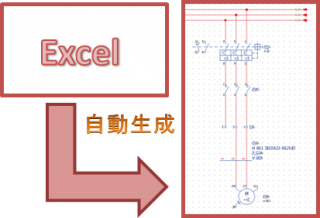

Engineers have the freedom to use the system as they see fit. Engineers can now use the extra time to tackle creative tasks.” Components and structures must be defined in advance, but the effort pays off, which is why GreyLogix is gradually phasing in EEC One in all of its business units. Thomas Besser explains, “You can generate 50 to 60 per cent of the project with the help of this automated design process. The diagram still requires individual adjustments, but it offers a good foundation and saves a lot of time. Next, he selects components from an individually configured list, such as “75 kW motor,” hits the “configuration” button, and receives the wiring diagrams. This requires a specific approach: the engineer enters basic parameters into a table, such as the voltage for instance. The software allows schematics to be generated automatically, based on an Excel interface. We’re continually working on this.”Įplan Engineering Configuration One (EEC One) is a recent addition to the tools that GreyLogix uses for electrical engineering. We want to offer our customers additional value: be smarter and work more intelligently.

GreyLogix has always relied on a high degree of automation: “We recognized early on that we have to be strong in project and process management. “It makes expertise and experience all the more important.” This applies to programming, which constitutes the majority of the work, but also to electrical design and switchgear cabinet engineering. “We don’t have any standard projects, so there is no learning curve either,” says Thomas Besser, Team Leader for the CAE Centre of Excellence. This is why their design teams are organized into various business units that each focus on specific market segments such as oil and gas, food and beverage and the chemical/pharmaceutical industries. In business for the past fifteen years, the company specializes in large automation technology projects that require engineering expertise as well as industry-specific know-how. With 650 employees, GreyLogix is among the largest experts in designing automation technology solutions. JBilfinger GreyLogix, based in Flensburg, Germany, is now working with the EEC One from Eplan – cutting the time needed for schematic creation in half. Bilfinger GreyLogix uses Engineering Configuration One (EEC One) for control cabinet manufacturing.

0 kommentar(er)

0 kommentar(er)